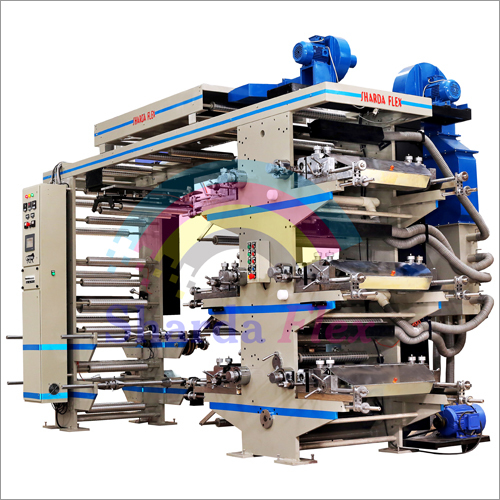

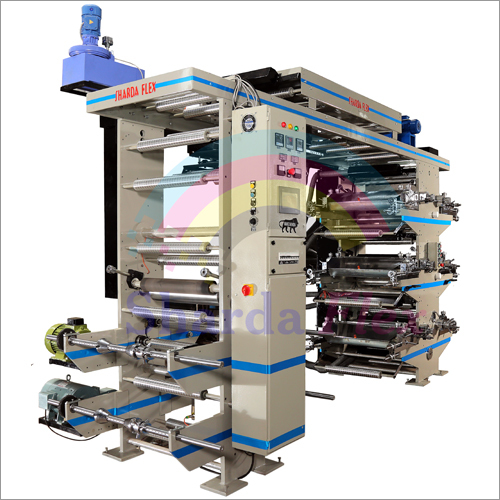

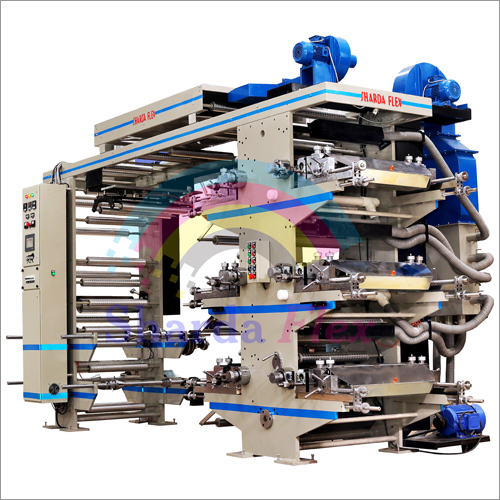

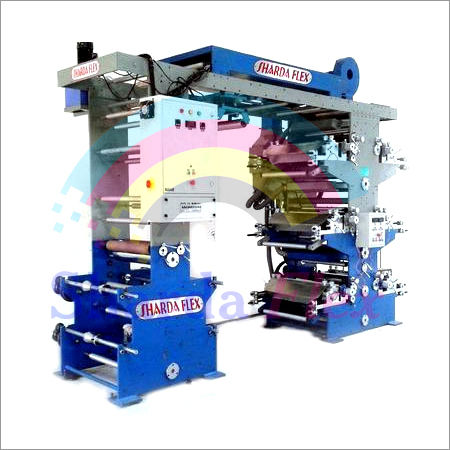

Six Color Flexographic Printing Machine

Product Details:

- Product Type Six Color Flexographic Printing Machine

- General Use Industrial printing on varied packaging materials

- Printing Material Paper, Plastic film, Non-woven fabric, Laminates

- Type Automatic flexographic printing press

- Capacity 60 Kg/hr

- Weight (kg) Approx. 6000 kg

- Computerized Yes

- Click to View more

Six Color Flexographic Printing Machine Price And Quantity

- 1 Number

- 1600000.00 - 2500000.00 INR/Number

- 1000.0 INR/Number

Six Color Flexographic Printing Machine Product Specifications

- PLC-based electronic control

- 2.38 - 7.0 mm (plate)

- Six color

- Roll-fed, max width 1300 mm

- Paper, Plastic film, Non-woven fabric, Laminates

- Industrial printing on varied packaging materials

- Yes

- Maximum 1200 mm

- Approx. 6000 kg

- Six Color Flexographic Printing Machine

- Automatic flexographic printing press

- 380V/50Hz

- 8000 x 2100 x 2600 mm

- 60 Kg/hr

- 60-100 m/min

- Available

- 270 - 1000 mm

- 120 m/min

- Automatic pneumatic

- Yes

Six Color Flexographic Printing Machine Trade Information

- 1 Number Per Month

- 1 Months

- South India, Central India, West India, North India, East India, Gujarat, Karnataka, Kerala, Arunachal Pradesh, Chhattisgarh, Haryana, Himachal Pradesh, Jammu and Kashmir, Madhya Pradesh, Maharashtra, Nagaland, Rajasthan, Sikkim, Tamil Nadu, Telangana, Tripura, Pondicherry, Uttar Pradesh, Uttarakhand, All India, Meghalaya, Manipur, Andhra Pradesh, Chandigarh, Daman and Diu, Goa, Jharkhand, Odisha, Punjab, Assam, Andaman and Nicobar Islands, West Bengal, Lakshadweep, Mizoram, Bihar, Delhi, Dadra and Nagar Haveli

Product Description

Six Color Performance Series is a fully automatic industrial-class printing unit that is used to make high-quality prints on various types of material sheets such light density polyethylene, non-woven fabrics, paper, high-density polyethylene film, and many more. It is also provided with a tensioner control system that helps to easily adjust the film stretch. The frame is provided with an in-built control panel to easily operate this heavy-duty Six Color Performance Series printing machine.

The Machine is suitable for printing on LDPE, HM, HDPE,PP,BOPP,Non-Woven,Paper etc.

Double winder & unwinder.

Reverse Printing Arrangement (6,1+5,2+4,3+3)

Product Details

|

Voltage |

440V |

|

Machine Type |

Automatic |

|

Material |

Mild Steel |

|

Brand |

Sharda Flexo |

|

Model Name/Number |

Performance Series |

|

Printing Width |

30 inch |

|

Frequency |

50 Hz |

|

Power Source |

Electric |

|

Color Printing |

Color Printing |

|

Usage/Application |

LDPE, HM, HDPE, PP, BOPP, Non-Woven, Paper Printing |

|

Number Of Colors |

6 |

Optional Features :

- Tension Control System

- Web Aligner

- Doctor Blade System with Ceramic Roller

- Chambered Doctor Blade System with Ceramic Roller

- Printing width (In.) 12 14 18 24 30 34 40

- Web width (In.) 14 16 20 26 32 36 42

- Heater (KW) 10 10 12 15 18 21 22

- Main Drive 5 hp

- Blower 3 hp + 2 hp

- Printing repeat 8 to 40

- Max reel dia 30

- Printing speed 80* Meter / Min (Ink Tray System)

- 150* Meter / Min (Chambered Doctor Blade System)

Superior Printing Precision

This six-color flexographic press integrates high-resolution ceramic anilox rollers and a sensitive registration system for sharp, repeatable prints. Achieving 0.15 mm registration accuracy, it consistently delivers professional-quality results on various packaging substrates, from paper to flexible films, enhancing your product presentation and brand clarity.

Efficient Integrated Drying System

With its advanced hot air and infrared (IR) dryer, the machine ensures immediate drying of inks, supporting faster production speeds. This dual drying approach not only prevents smudging and set-off but also guarantees optimal adhesion on diverse materials, streamlining your workflow for complex multi-color jobs.

FAQ's of Six Color Flexographic Printing Machine:

Q: How does the automated ink circulation system benefit the printing process?

A: The automatic ink circulating pump maintains consistent ink flow and viscosity, reducing manual intervention and minimizing downtime. This ensures uniform color distribution across all six print stations, delivering high-quality prints while optimizing ink usage.Q: What materials can be printed using this flexographic machine?

A: This machine supports printing on paper, plastic films, non-woven fabrics, and laminates. Its robust design and precision controls make it suitable for a broad range of industrial packaging applications.Q: When is the pre-heating system most advantageous during operation?

A: The pre-heating system is particularly useful during machine start-up and material changes. It rapidly warms critical components, reducing waiting times and ensuring that printing begins with optimal ink flow and substrate condition.Q: Where can the Six Color Flexographic Printing Machine be installed?

A: This press is designed for installation in industrial facilities, including large-scale packaging, printing, and converting plants. Its capacity and dimensions (8000 x 2100 x 2600 mm) suit production environments requiring high throughput and multi-substrate capability.Q: What process controls are available to operators?

A: Operators manage the machine through a PLC-based electronic control system and touchscreen HMI. Automated tension controllers, web guides, and registration systems streamline setup and maintain precise printing during runs.Q: How energy efficient is the printing machine?

A: Engineered for energy efficiency, the integrated drying systems use both hot air and IR, and the machine operates below 80 dB(A), contributing to lower energy consumption and a quieter production environment, benefiting long-term operational costs.Q: What are the primary benefits of high registration accuracy in flexographic printing?

A: High registration accuracy (0.15 mm) ensures precise alignment of multiple colors, minimizes waste, and delivers crisp, professional visuals on every print job-critical for premium packaging and brand consistency.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

English

English Spanish

Spanish French

French German

German Italian

Italian Chinese (Simplified)

Chinese (Simplified) Japanese

Japanese Korean

Korean Arabic

Arabic Portuguese

Portuguese