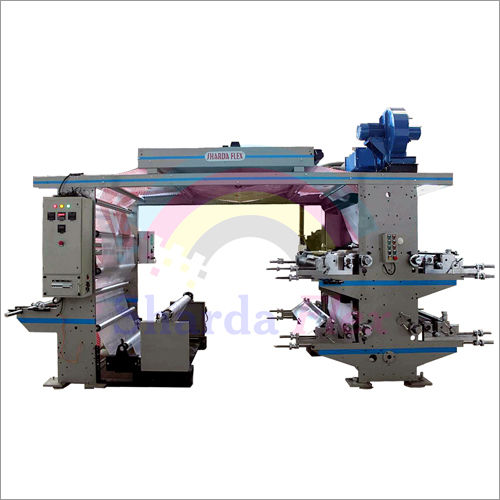

Four Color Flexographic Printing Machine

Product Details:

- Product Type Four Color Flexographic Printing Machine

- General Use High-speed flexographic printing on packaging materials

- Printing Material Paper, plastic film, non-woven fabric, laminated materials

- Type Flexo Printing Machine

- Capacity Up to 60 meters/minute

- Weight (kg) ~3500 kg

- Computerized Yes

- Click to View more

Four Color Flexographic Printing Machine Price And Quantity

- 1400000.00 - 2500000.00 INR/Number

- 1 Number

- 7.5 KW

- 0.02-0.30 mm

- Magnetic powder tension control

- Chambered doctor blade

- Hot air / Electric heaters

- Water-based or solvent-based

- 1000 mm

- 80 dB

- Ceramic / steel, optional lines per inch

- 26 KW

- 0.15 mm

Four Color Flexographic Printing Machine Product Specifications

- Flexo Printing Machine

- Four Color Flexographic Printing Machine

- Automatic Pneumatic Plate Lifting

- ~3500 kg

- Yes

- High-speed flexographic printing on packaging materials

- Up to 60 meters/minute

- Up to 70 meters/min

- 200 mm - 1100 mm

- PLC Based

- 900 mm (max)

- 0.5 - 4 mm

- Standard: Blue & White

- Paper, plastic film, non-woven fabric, laminated materials

- 5200 mm x 2200 mm x 2400 mm

- 850 mm (max)

- Equipped with Electric Positioning System

- 10-60 meters/min

- Yes

- 380V/50Hz 3-Phase

- 7.5 KW

- 0.02-0.30 mm

- Magnetic powder tension control

- Chambered doctor blade

- Hot air / Electric heaters

- Water-based or solvent-based

- 1000 mm

- 80 dB

- Ceramic / steel, optional lines per inch

- 26 KW

- 0.15 mm

Four Color Flexographic Printing Machine Trade Information

- 1 Number Per Month

- 1 Months

Product Description

Six HDPE Woven Sack Bag Printing Machine is a high-speed print unit that is used to make high-quality prints with multiple colors on various types of materials. It is designed by our skilled professionals by using premium-class materials and high-performance drives that make it sturdy as well as efficient. The sturdy design of this unit prevents damages due to uneven forces produced during the operation. The offered Six HDPE Woven Sack Bag Printing Machine is capable to make prints on sheets with a maximum width of 14 inches at a speed of 50 meters per minute.

Product Details

Voltage | 440V |

Machine Type | Automatic |

Material | Mild Steel |

Brand | Sharda Flex |

Printing Width | 24 inch |

Printing Speed | 50m/min |

Frequency | 50 Hz |

Power Source | Electric |

Color Printing | Color Printing |

Usage/Application | LDPE, HM, HDPE, PP, BOPP, Non-Woven, Paper Printing |

Number Of Colors | 4 |

Superior Printing Precision

With a printing precision of 0.15 mm, the Four Color Flexographic Printing Machine is engineered for high-quality, detailed output. The combination of advanced control systems and chambered doctor blade technology helps maintain consistent print quality across long runs, making it suitable for demanding packaging applications.

Versatile Substrate and Ink Compatibility

From paper to plastic film, non-woven fabrics, and laminated materials, this machine accommodates a wide substrate range from 0.02 to 0.30 mm thickness. Both water-based and solvent-based inks can be deployed, providing versatility to adjust print jobs according to specific packaging requirements or client preferences.

Efficient Operation and Rapid Job Change

Automatic systems, such as pneumatic plate lifting and the Electric Positioning System (EPS), streamline operation and speed up job changeovers. Magnetic powder tension controls and a powerful 7.5 KW main drive motor support smooth unwinding and rewinding, allowing continuous and efficient high-speed printing.

FAQs of Four Color Flexographic Printing Machine:

Q: How does the Four Color Flexographic Printing Machine achieve high printing precision?

A: The machine uses a combination of ceramic or steel anilox rollers, a PLC-based control system, and an automatic pneumatic plate lifting mechanism. These features work together to maintain fine registration accuracy of 0.15 mm, ensuring clear, consistent print results.Q: What types of materials can be printed on this flexo machine?

A: The machine supports a broad range of substrates including paper, plastic film, non-woven fabric, and laminated materials, with thicknesses from 0.02 to 0.30 mm. This makes it suitable for various packaging applications.Q: When should I use water-based ink versus solvent-based ink with this machine?

A: Water-based ink is generally preferred for environmentally friendly or food-grade packaging, while solvent-based ink offers faster drying and is suited for high-speed runs or materials that may require additional adhesion and durability.Q: Where is this machine manufactured and supplied from?

A: This high-speed flexographic printing machine is designed, manufactured, exported, and supplied by reputable companies in India, serving local and international packaging markets.Q: What is the process for changing jobs or print designs on this machine?

A: The machines automatic pneumatic plate lifting system and Electric Positioning System (EPS) make it quick and easy to switch printing plates and adjust settings, enabling rapid job changes with minimal downtime.Q: How is unwinding and rewinding controlled during printing?

A: Unwinding and rewinding are managed using a magnetic powder tension control system, ensuring stable tension and precise substrate handling throughout the printing process.Q: What are the main benefits of using this four color flexographic printing machine?

A: Key advantages include high-speed and high-precision printing, energy-efficient drying systems, user-friendly PLC controls, and the flexibility to print on various materials with rapid job change capabilities.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

English

English Spanish

Spanish French

French German

German Italian

Italian Chinese (Simplified)

Chinese (Simplified) Japanese

Japanese Korean

Korean Arabic

Arabic Portuguese

Portuguese